The Problem

- 20% annual apple wastage driven by demand and market access gaps

- 50% struggle to find suitable markets for table apples

- 60% prefer a noninvasive handheld device for chemical and quality assessment

- 65% willing to invest $1500 in such a solution

- 50% open to pilots or research programs

* Survey conducted at the Minnesota Apple Growers Association Annual Meeting

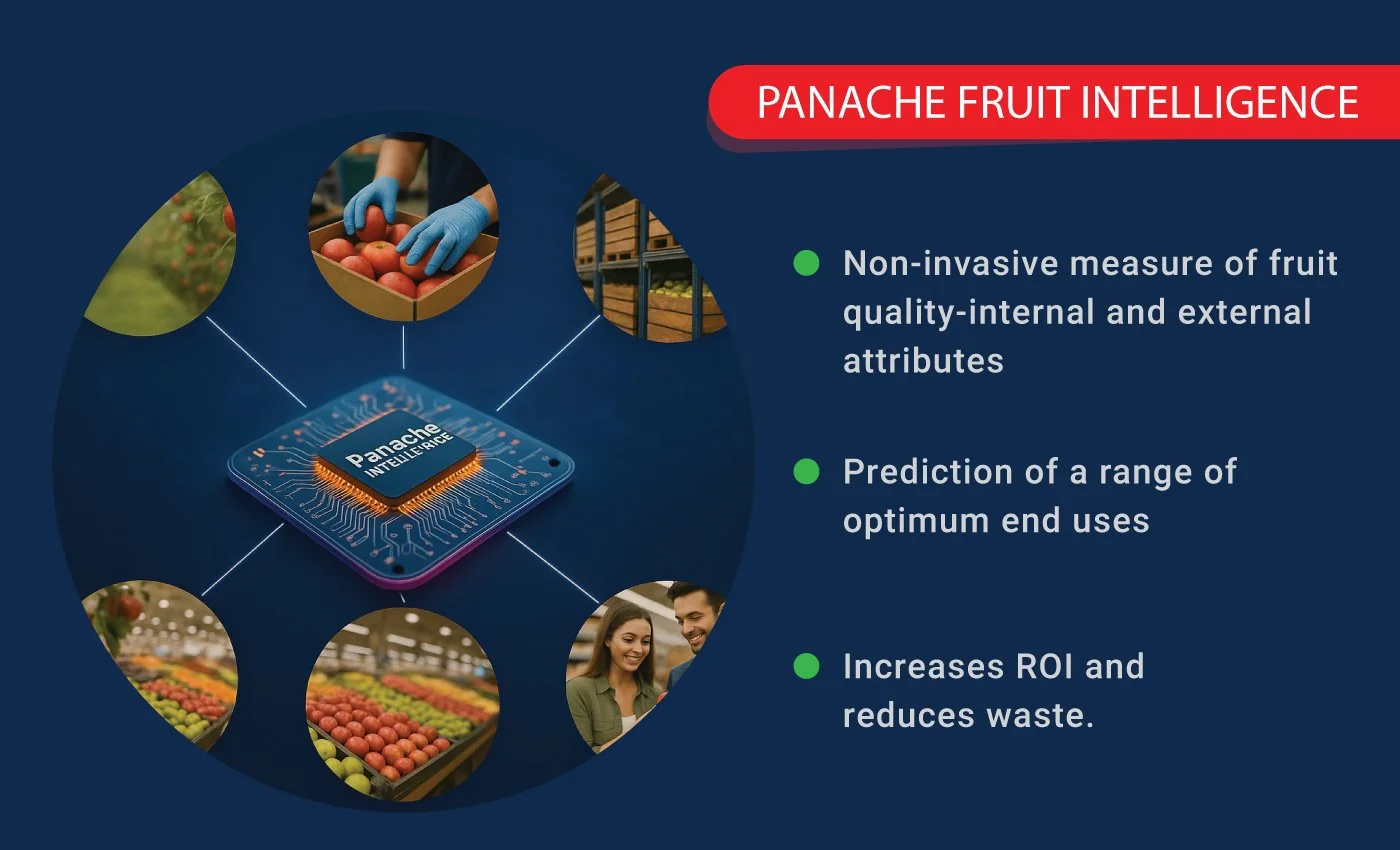

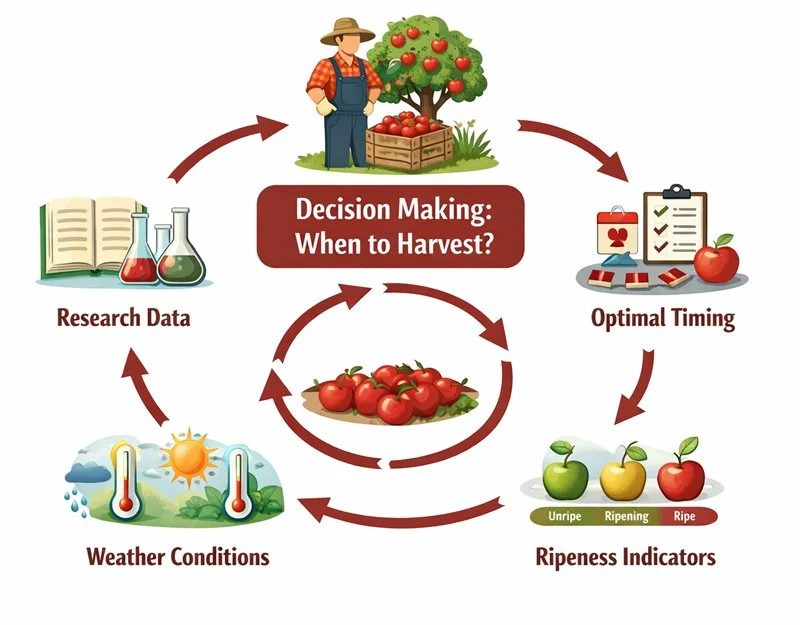

A different approach

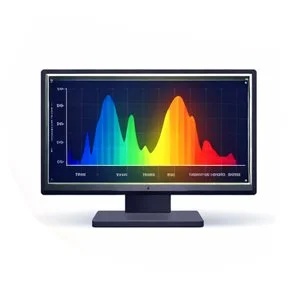

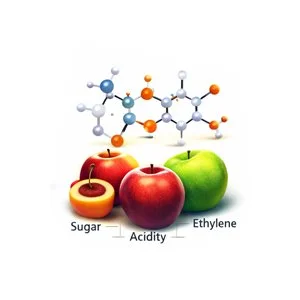

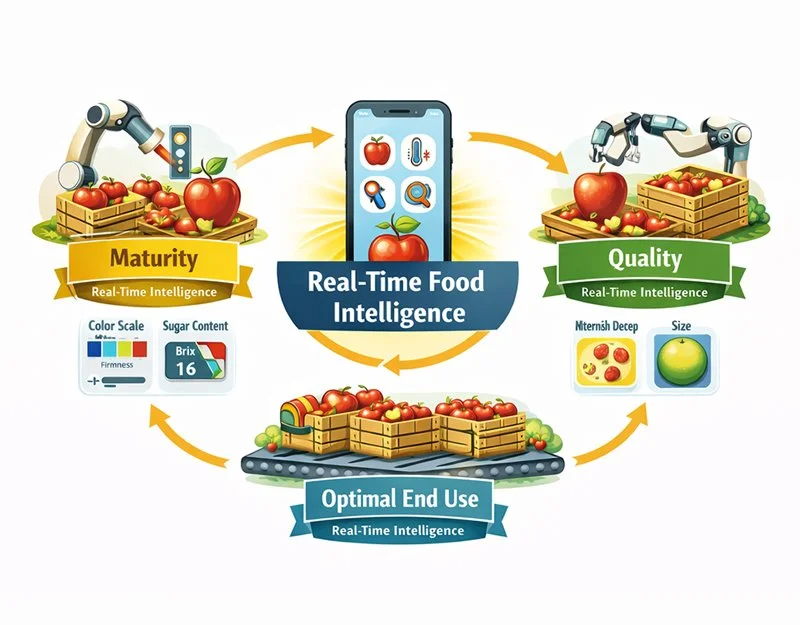

By evaluating multiple chemical and non-chemical attributes simultaneously and non-invasively, the Panache Intelligence software platform predicts with >75% accuracy the optimum end use of the apple and pricing strategies

What this enables

Panache enables earlier, better-informed decisions that preserve value, reduce waste, and align incentives across the supply chain.

Food waste is rarely caused by poor production. It is caused by decisions made too late or with incomplete information.

Across the supply chain

Panache supports decision-makers wherever quality, timing, and routing decisions occur.

That includes orchard operators, packing houses, processors, distributors, and retailers. Rather than optimizing for a single workflow or handoff, Panache provides a shared intelligence layer that can be applied across the supply chain. As deployment evolves, the platform adapts to different environments while delivering consistent insight at each decision point.

Panache enables each participant to make better decisions independently while staying aligned across the system.

Built in the real world

The core value, however, is the intelligence platform which in turn will improve and expand to produce customized beverages - the next frontier for the CPG - consumer packaged goods - sector.

Why now

Labor constraints, climate variability, and margin pressure are increasing the cost of poor decisions. Panache enables clarity where it has historically been missing, helping the supply chain reduce waste, protect value, and align outcomes.

Explore the platform

![Turmeric Samatva Swing-[Case of 6]](https://images.squarespace-cdn.com/content/v1/625055bc4a10644cf97ca1ad/1713218202337-IHEQQG4D7H5YHB6BM6P2/Panache-turmeric-2024.jpg)

![Ginger Cheeky Zing-[Case of 6]](https://images.squarespace-cdn.com/content/v1/625055bc4a10644cf97ca1ad/1713207690978-RXQJ7IM21HUK2B71LQP6/Panache-ginger-2024.jpg)

![Aronia Berry Bold North-[Case of 6]](https://images.squarespace-cdn.com/content/v1/625055bc4a10644cf97ca1ad/1713218064736-SYE36DOYMYYX58NND2T1/panache-aronia-berry-2024.jpg)

![Sour Cherry Piquant Zing-[Case of 6]](https://images.squarespace-cdn.com/content/v1/625055bc4a10644cf97ca1ad/1713218260752-R3ENLHRFMF45DLJICMRO/Panache-sour-cherry-2024.jpg)